Wood Products - Air, Water, Waste

Managing our Impact

We are committed to protecting air quality, reducing water consumption, and reducing our waste in order to protect our environment.

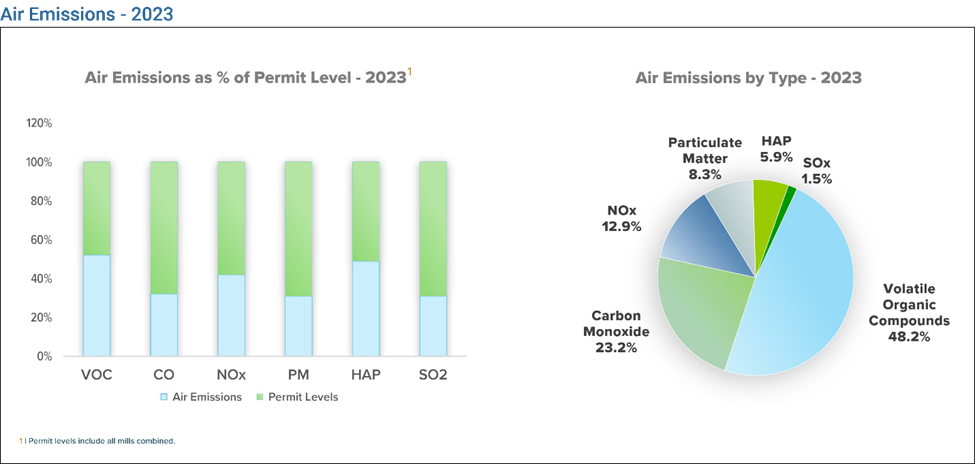

PROTECTING AIR QUALITY

Air emissions from our wood products facilities are generated primarily from the combustion of fuels to generate energy. Combustion of residual wood in boilers that produce steam energy for use in the kilns to dry lumber produces combustion-typical emissions such as carbon monoxide (CO), nitrogen oxides (NOx), sulfur dioxide (SO2), Hazardous Air Pollutants (HAPs), and particulate matter (PM). When drying lumber in a kiln, wood extractives in the form of volatile organic compounds (VOCs), HAPs, and PM (formed from the condensation of VOCs) are released. The air emissions are limited under several federal and state regulatory programs such as the National Emissions Standard for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS). The performance standards created by these regulatory programs are implemented at our facilities in permitting programs that establish source-specific operating conditions. These permits guide our facilities in their ongoing efforts to meet the regulatory performance standards.

We regularly measure and report air emissions at each of our facilities and monitor compliance with emission limits for each source and emission type established in our permits. Stack emissions from larger sources like wood-fired boilers are measured by qualified third-party testing companies on a set schedule defined in our permits. The data are regularly collected to verify compliance with various emission limits for select pollutants. We use various technologies at our manufacturing facilities to monitor key emission sources and associated emissions control devices to ensure compliance with applicable air emissions standards. Quality assurance and quality control procedures have been implemented to ensure data integrity and third-party specialists are used to perform periodic maintenance and calibration checks on the facilities that use Continuous Opacity Monitoring Systems. In addition, agency-accepted work practice standards are used to minimize air quality impacts and each site is subject to an internal audit every other year.

We evaluate the operation and maintenance of all our emission sources and their associated control devices. Proper design, operation, and maintenance of the equipment minimizes emissions and is an important part of our air quality commitments. Our facilities also utilize cyclones, baghouses, and/or electrostatic precipitators to control particulate emissions. In addition, our St. Maries, Idaho plywood facility operates special air pollution control equipment to satisfy requirements under applicable regulations. In compliance with the applicable regulations, exhaust from the heated zones of the plywood veneer dryers is collected and routed to a regenerative catalytic oxidizer (RCO) for emissions control.

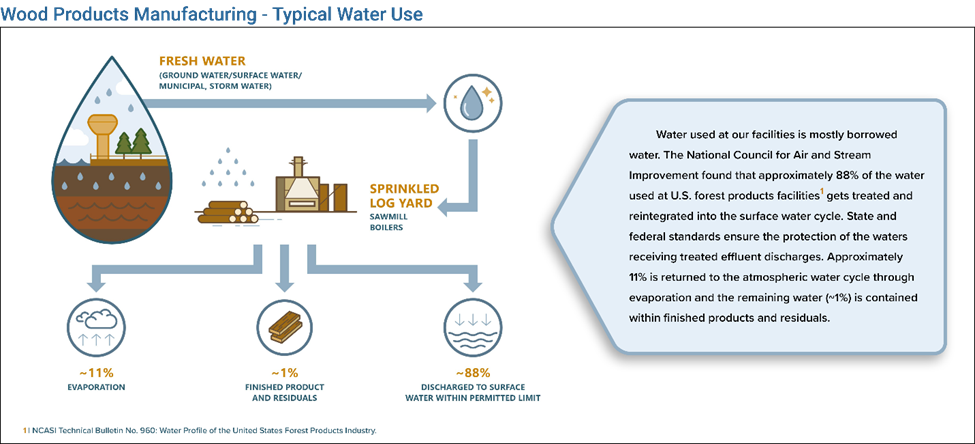

REDUCING WATER CONSUMPTION

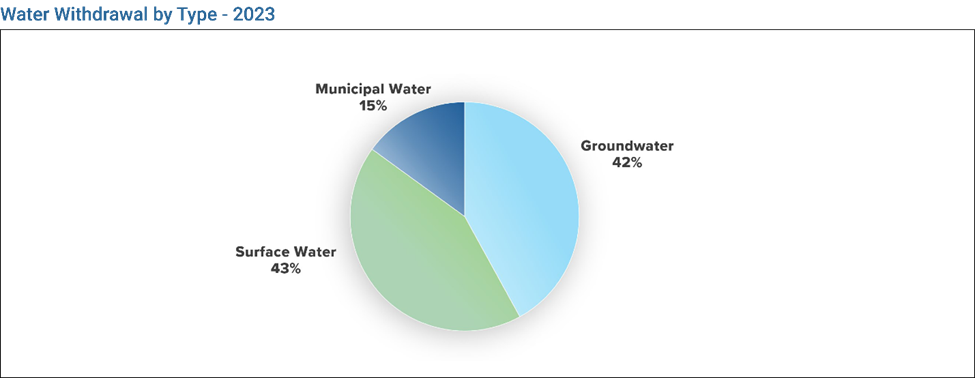

The water used in our wood products facilities is obtained from surface water, groundwater, and municipal sources. It is used principally for watering log decks, saw cooling, make-up water at the boilers for steam production, and fire protection. Water withdrawals are minimized through extensive reuse and recycling, especially at the log deck. The water that is discharged is sent to settling ponds for solids removal prior to being released. Water loss across the facilities is mostly due to evaporation from log watering activities.

Discharges of water are monitored under two permit programs. The National Pollutant Discharge Elimination System (NPDES) is the permitting program that covers discharges of both wastewater and stormwater in the United States. The wastewater permitting program allows for only certain types of discharges, establishes monitoring requirements, and sets discharge limitations. PotlatchDeltic has NPDES wastewater discharge permits at our St. Maries, Waldo, Warren, and Ola manufacturing facilities because these facilities occasionally discharge to surface water. The stormwater permitting program establishes monitoring requirements and discharge benchmarks for stormwater to protect water quality.

The NPDES permits have parameter limits and benchmarks for pollutants such as zinc, chemical oxygen demand (COD), and total suspended solids (TSS). Wastewater permits have set monitoring regimes that include weekly, quarterly, semi-annual, and/or annual sampling for various parameters. Stormwater monitoring occurs when a qualifying precipitation event that results in runoff occurs. Sampling is conducted by our on-site environmental Team Members or by qualified environmental consultants. As required, we submit the data to the appropriate regulatory agency within a timeline defined in the permit. NPDES permits can have additional immediate notification requirements if a limit is exceeded, and the stormwater permits have requirements to develop corrective actions if a benchmark is exceeded. The stormwater program also requires additional routine site inspections to confirm proper function of stormwater controls. Periodic internal audits are conducted to assess whether that the required inspections, corrective action planning, and reporting are being performed.

Water is relatively abundant at all our locations. Two of our Arkansas facilities, Warren, and Waldo, however, are in critical groundwater areas due to reliance on the Sparta Aquifer. In 2024, total water sourced at Warren was 6% from municipal water and 94% from groundwater; however, municipal water supplied to Warren is partially sourced from the Sparta Aquifer. Total water for Waldo in 2024 was sourced 82% from groundwater and 18% from municipal water. Municipal water supplied to Waldo is surface water sourced from Lake Columbia.

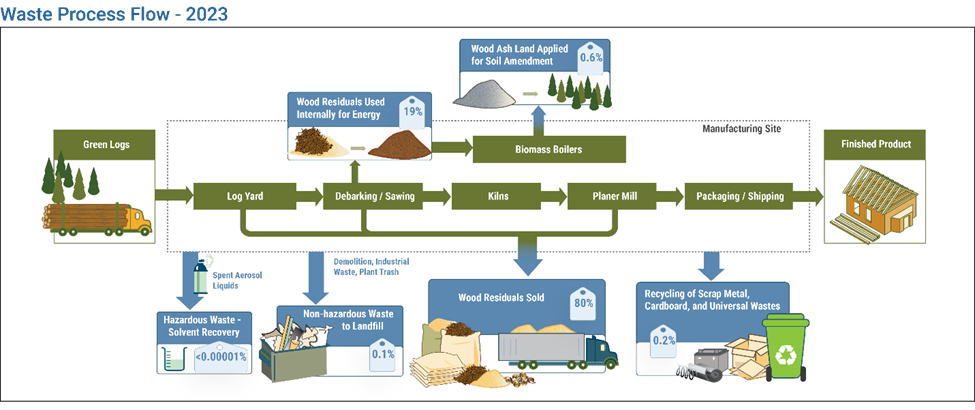

REDUCING WASTE

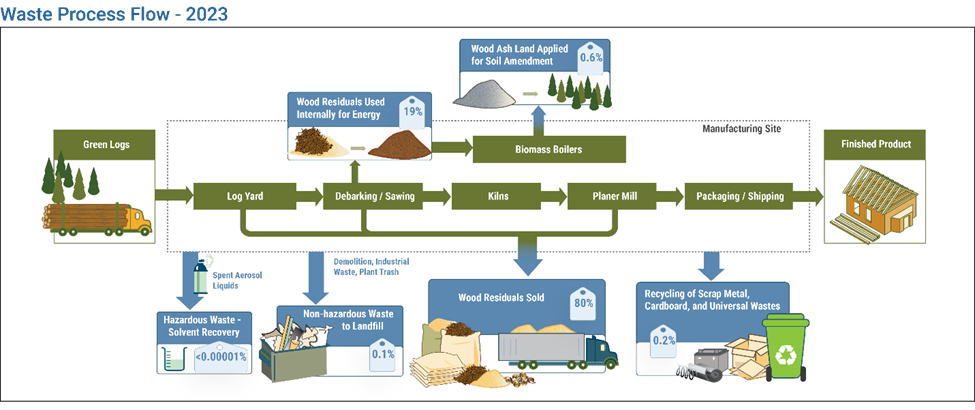

Wood residuals constitute most of the waste from our wood products production. They account for approximately 99% of the waste left over after converting green logs to finished lumber. Approximately 81% of residuals generated are sold for a wide range of end uses, with the remainder used internally for energy. Wood ash is also generated from burning wood residuals for fuel in the boilers. In many of our locations in Arkansas and Minnesota, wood ash is land applied for soil amendment as a soil liming substitute in agricultural and silvicultural applications under programs administered under the Departments of Agriculture. This application provides a natural means of increasing alkalinity while supplying certain micronutrients that help plants thrive.

The remainder of our wastes principally consist of a range of non-hazardous wastes which are either reused, recycled, or sent to landfills. The primary non-hazardous waste streams generated by our wood products facilities, other than wood residuals and wood ash, include trash, industrial waste, scrap metal, and cardboard.

Very small quantities of hazardous waste are generated at some or our facilities through the processing of waste aerosol cans in order to render them safe for disposal. This involves draining each individual can to collect any remaining liquid contents. The final disposal method for these liquids is done by a licensed third-party treatment and disposal facility and involves refining the waste liquid to recover useable solvents prior to burning for energy recovery. The steel aerosol cans are recycled after they are emptied.

Universal waste is also generated at our facilities and includes materials such as fluorescent and HID lamps, mercury-containing equipment such as thermostats, and certain types of batteries. These wastes are sent to licensed universal waste handling facilities for recycling. All wastes are stored, recycled, and transported in compliance with applicable laws. We are committed to minimizing hazardous waste.

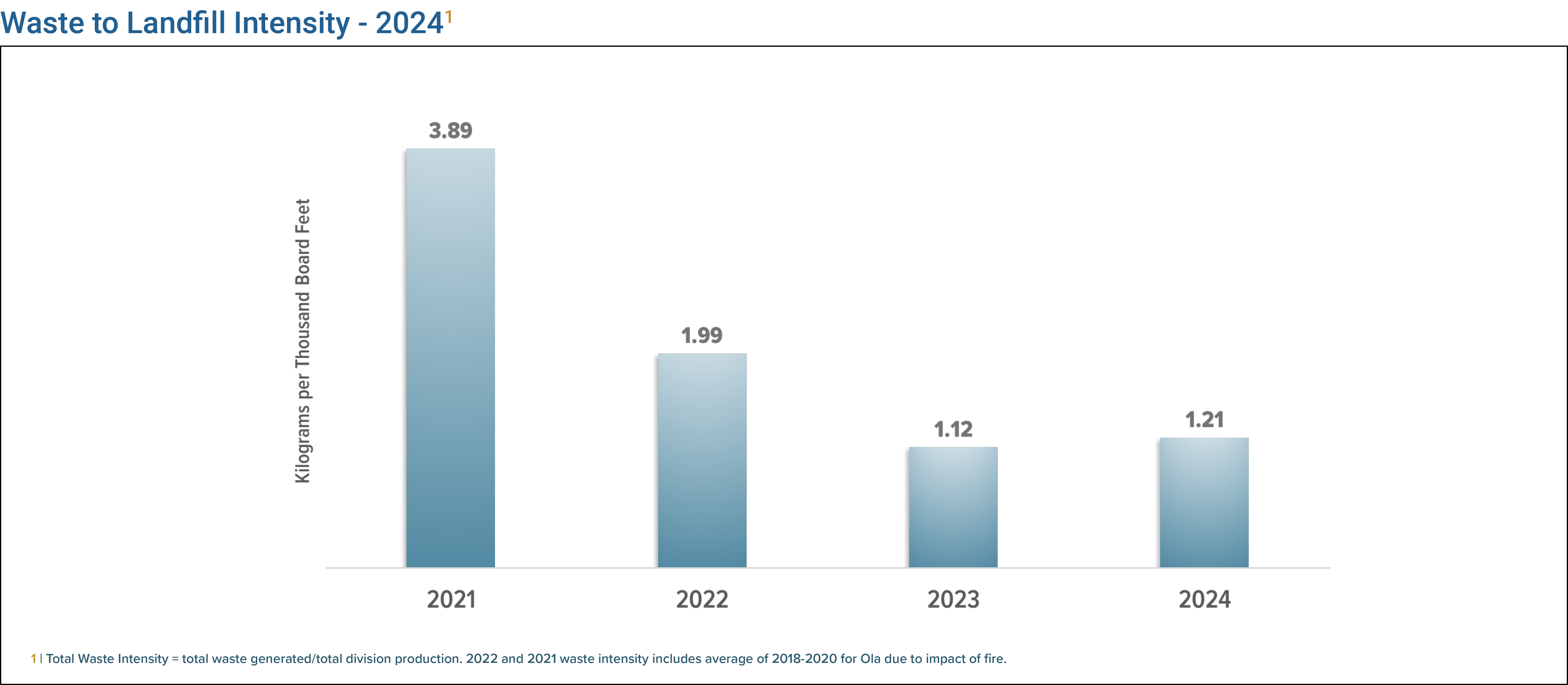

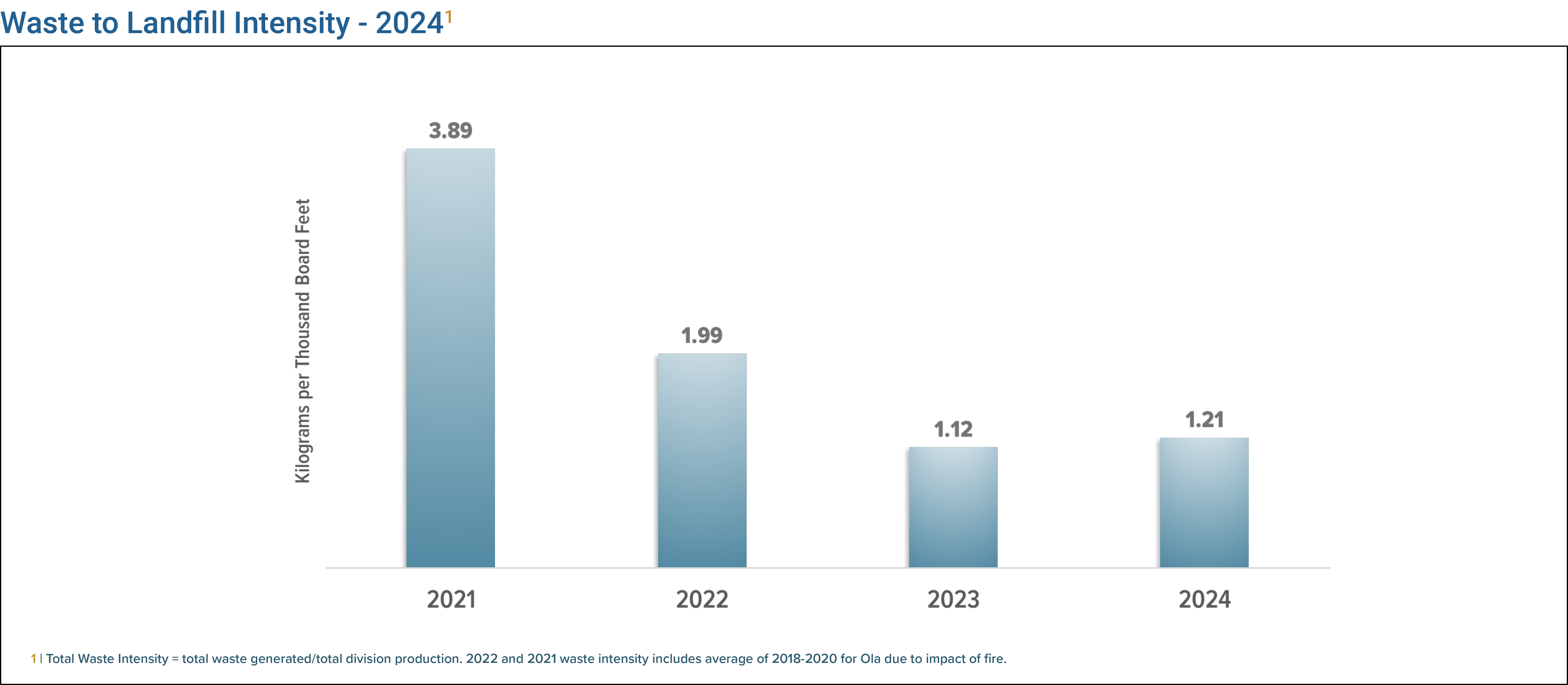

Since the base year of 2021, we have reduced non-hazardous landfill waste by 68%. In 2024, the implementation of the Waldo modernization project and an increase in division production resulted in an approximate 10% increase versus 2023 in measured landfilled solid waste across the Wood Products Division. Excluding Waldo, the mills decreased landfill solid waste ~ 2.5% on a unit basis.

The City of St. Maries in Idaho has undertaken a multi-party effort to improve local air quality. The area is prone to natural air inversions which can trap particulate matter, which typically consists of combustion products (i.e., smoke). The city of St. Maries is participating in PM Advance, a U.S. Environmental Protection Agency (EPA) program to proactively address air quality improvement opportunities within the St. Maries airshed through voluntary efforts.

LEARN MORE ABOUT WOODSTOVE CHANGEOUT

In 2022, we installed an automated plywood panel repair system in St. Maries, Idaho. Previously, the plywood plant relied on two patch lines staffed by a team of up to 12 Team Members. The operators identified panel flaws, routed out defects, and filled them with patch compound using applicator guns.

LEARN MORE ABOUT PLYWOOD PATCH LINE AUTOMATION

Hazardous waste generated at our facilities consists of the drained contents of spent aerosol cans and amounted to a total of 367 pounds in 2022. The final disposal method for this waste is done by a licensed third-party treatment and disposal facility and involves refining the waste liquid to recover useable solvents prior to combusting for energy recovery. The steel aerosol cans are recycled after they are emptied.

LEARN MORE ABOUT WASTE REDUCTION EFFORTS