Wood Products Energy

Responsible Energy Usage

Reducing energy consumption and conserving resources are integral to our success. Energy consumption has accompanying financial and environmental costs that vary depending on the type of energy used. We endeavor to minimize these costs by emphasizing conservation and the use of renewable energy in our operations.

ENERGY CONSUMPTION

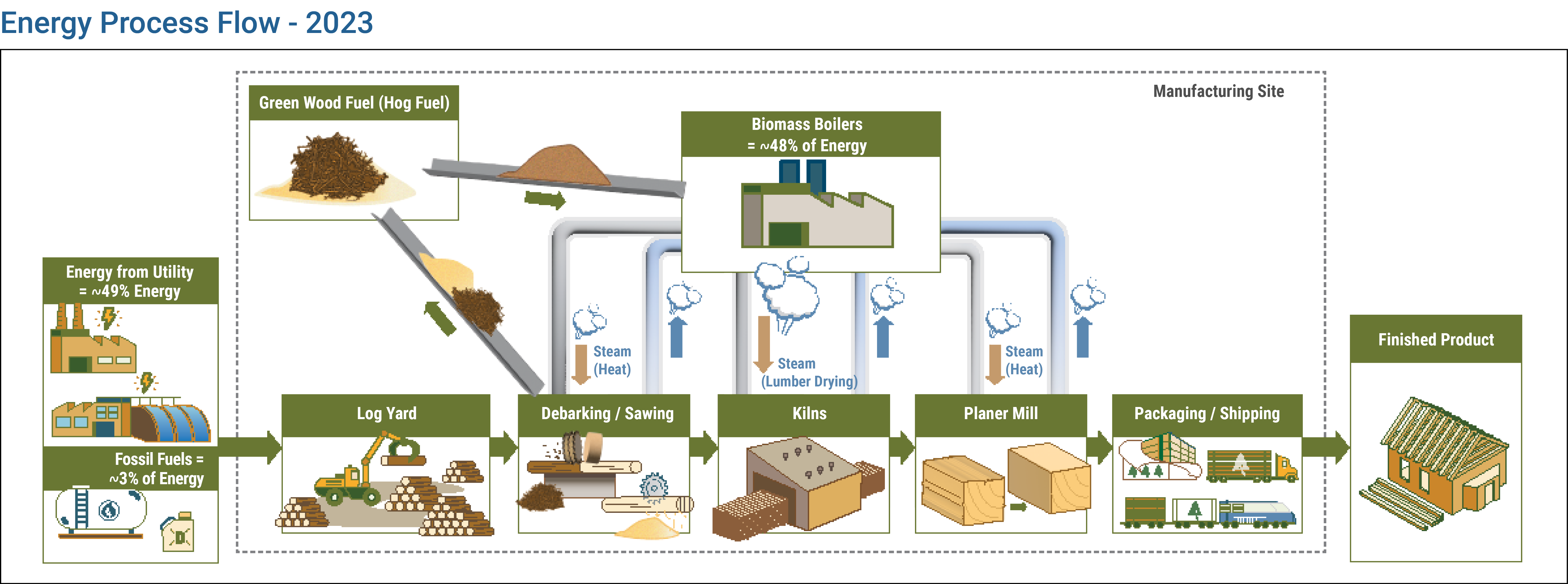

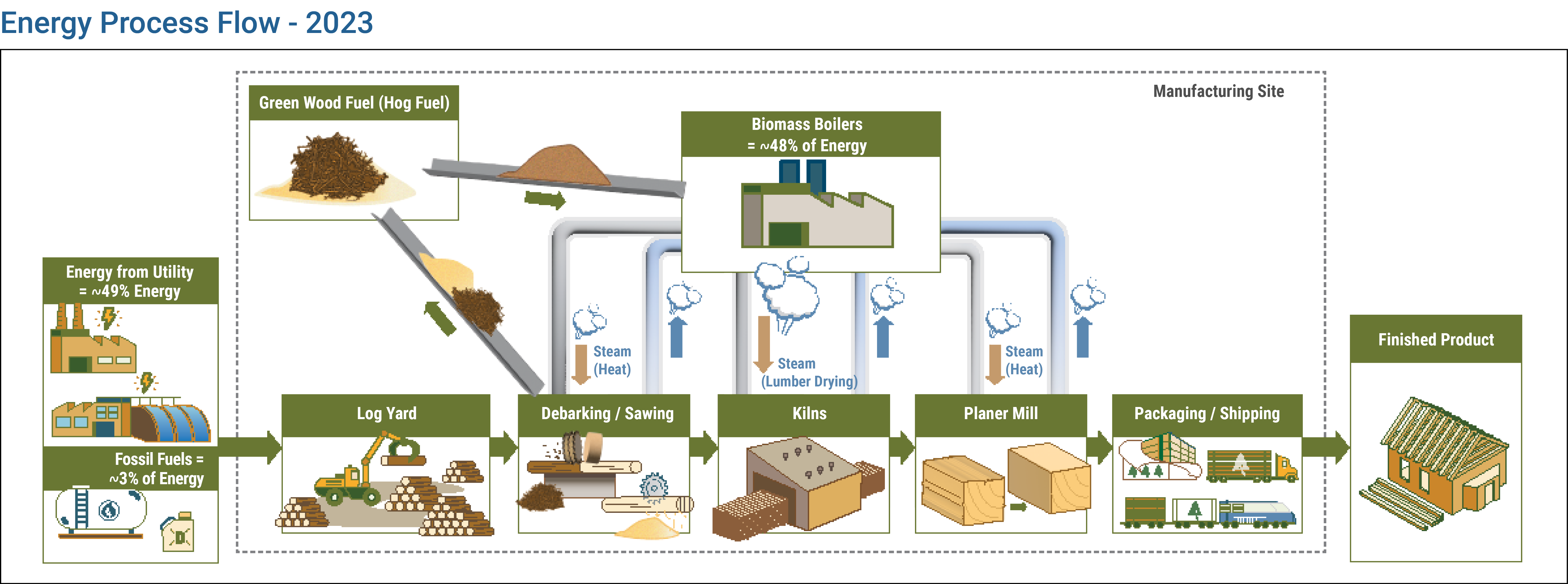

Energy needs at our wood products facilities are principally supplied by residual wood-fired boilers, purchased electricity, and some fossil fuels. Residual wood from lumber production is utilized in boilers to produce steam energy to dry wood in the kilns and to provide comfort heating. Purchased electricity is used to run process equipment and for heating and cooling. Diesel fuel is predominantly used in mobile equipment. In addition, there is one facility with a supplemental natural gas-fired boiler and two facilities with a natural gas direct-fired kiln. In 2024, energy consumed consisted of ~46% purchased electricity, ~49% renewables and ~5% non-renewable fossil fuels.

Another energy consuming piece of equipment is our regenerative catalytic oxidizer (RCO), which is an air pollution control device at our plywood mill. The RCO uses propane to maintain a sufficient temperature to destroy air pollutants before they’re released. The catalyst in the RCO allows for a lower temperature, therefore reducing propane usage.

Residual wood-fired boilers represent the heart of our wood products facilities. These boilers create steam that provides heat to our operations and power to our kilns where lumber is dried. At the St. Maries facility, the boilers also provide efficient and economical steam heat to the veneer dryers. The boiler energy is provided by renewable wood residuals in the form of hogged fuel. Hogged fuel is a mixture of bark, wood, and sawdust residuals from the manufacturing process that are ground up or “hogged” for better consistency. In 2024, our wood products facilities utilized an average of 19% of the wood residuals they produced as fuel in their boilers to generate thermal energy in the form of steam. In fact, wood residuals provide all the thermal energy needed to produce steam and to dry wood at our mills, except for the mills in Gwinn, Michigan and Ola, Arkansas, where wood residual fuel is supplemented with natural gas. Overall, this sustainable source of fuel provided on average ~49% of the 2024 energy requirements at our wood products facilities.

The sources of energy consumed at each mill vary depending on equipment configuration. The goal is to optimize the use of renewable fuels such as our wood residuals, within the physical equipment constraints while minimizing other environmental impacts. Our Warren, Arkansas and Bemidji, Minnesota wood products facilities obtain approximately half of their energy requirements from wood residuals. The Gwinn facility utilizes natural gas and other fossil fuels to meet about 19% of total energy needs. The natural gas fired boiler and kiln at Gwinn minimize emissions of criteria air pollutants such as particulate matter, carbon monoxide, and oxides of nitrogen compared to emissions from a biomass boiler. The regenerative catalytic oxidizer used to meet the National Emissions Standard for Hazardous Air Pollutants (NESHAP) at our St. Maries plywood facility also uses propane to destroy hazardous air pollutants from the veneer dryers.

The greenhouse gas emissions from the boilers burning wood residuals produce biogenic emissions. Even though the wood residuals emit CO2 when burned, the carbon emitted is part of the biogenic cycle rather than an increase in total carbon in the atmosphere from burning fossil fuels. Using residuals sourced from sustainably managed forests for energy reduces wood waste and has the additional benefit of avoiding carbon emissions from fossil fuels.

Energy efficiency is more than just reducing costs, it is also about long-term business resilience and environmental sustainability. In 2024, those efforts earned PotlatchDeltic’s Warren, Arkansas mill first place in Entergy Arkansas’ Energy Champion of the Year Award, recognizing its achievements in reducing energy waste and improving sustainability.

LEARN MORE ABOUT REDUCING ENERGY CONSUMPTION